PUMICE STONE USAGE IN STONE WASH

Stone washing of denim fabric gives ‘used’ or ‘vintage’ look on the garments. This is due to the varying degree of abrasion in the garment. Traditionally, stone washing of denim garments is carried out with pumice stones to achieve a soft hand and desirable look. The pumice stones having an oval and round shape with a rough surface work as an abradant in the washing cycle. The variations in shape, composition, hardness and porosity result in different washing effects in the denim fabric. During washing, these stones scrape off dye particles from the surface of the yarn of the denim fabric which shows a faded, worn out and brilliance effect in the denim fabric. From ring dyeing of denim fabric and heavy abrasion during stone washing, the fading is more apparent but less uniform. Stone washing makes the denim garments more supple so that they fit comfortably. To get the desired washed effect, the stone should be of proper hardness, shape and size. For heavyweight denim fabric, large and hard stones are suitable and also last longer. Similarly, smaller and softer stones are suitable for lightweight denim fabrics

The stones and denim are spun together in the large industrial washing

machines. The longer they are spun together the colour of the fabric would

get lighter with better contrasts. The time duration of this procedure is set

beforehand so as to avoid the tear and wear of the fabric. Thereafter the

fabric undergoes various other processes of rinsing, softening and finally

tumbles drying. These stonewashed fabrics are used different uses like-

garments making as well as for upholstery purpose.

Some

points should be followed during selecting Pumice stones, those are-

·

Pumice

stones should be selected according to the end product and the required amount of

effect needed on the garments.

·

Large and

hard stones are suitable for heavyweight garments.

·

Smaller and

soft stones are suitable for lightweight garments.

·

Ratio of

stone weight and garments weight is – [{(0.5 to 3)/1} kg].

·

Moisture

content of Pumice stones should be less than 5%.

·

Surface

properties of Pumice stones should be less than 5%.

·

Abrasion

loss of Pumice stones should be 35%.

· Aparent

density of pumice stones should be 0.5-0.75gm/cm3.

ADVANTAGES OF PUMICE STONE:

There

are some advantages of Pumice stones, those are mentioned in the below:

1.

Desired vintage effect on garments can be

easily achieved by using pumice stones.

2.

Washed garments can achieve more soft effect

by using pumice stones.

FLOW CHART OF STONE WASH:

Stone

washing process flow chart for any garments is in the following-

Garments loading with stone

↓

De-size

↓

Rinse (Two times)

↓

Stone wash

↓

Rinse (Two times)

↓

Softener

↓

Unload the garments

↓

Extracting

↓

Drying

The procedure is as follows:

1.

Load

stones into the machine.

2.

Load

garments into the machine (the ratio is usually 0.5–3.0 part weight stones to 1

part weight garments).

3.

Desize

with α-amylase enzyme and detergent. The liquor ratio is approximately 5–8:1.

4.

Rinse.

5.

Refill

and tumble with stones for 30–90 min, depending on the desired effect. The

Liquor ratio is 5–8:1 at 50–70°C. Scouring additives can also be used.

6.

Drain.

Separate garments from stones (garments can be transferred to another machine).

7.

Rinse.

8.

Apply

a softener (garments can be transferred to another machine for softening).

9.

Extract

and unload.

10.

Destone

and tumble dry.

11.

Press,

if required.

Softeners and/or lubricants can be added during Steps 3 and 5 to reduce the potential for creasing.

EFFECT

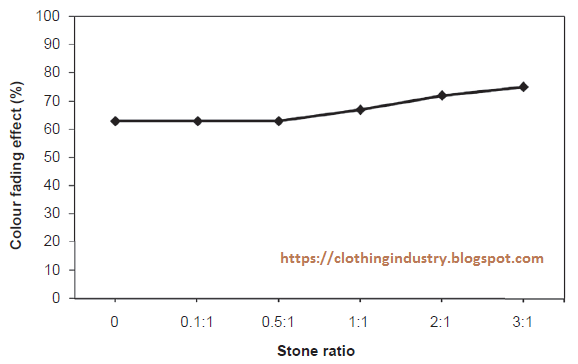

OF STONE RATIO:

Figure shows that with stone ratio below 0.5:1, no significant colour fading effect in

the denim garments is noted. When the stone ratio is high, the colour fading

effect becomes enhanced. However, too high a stone ratio may cause severe

abrasion leading to fabric damage.

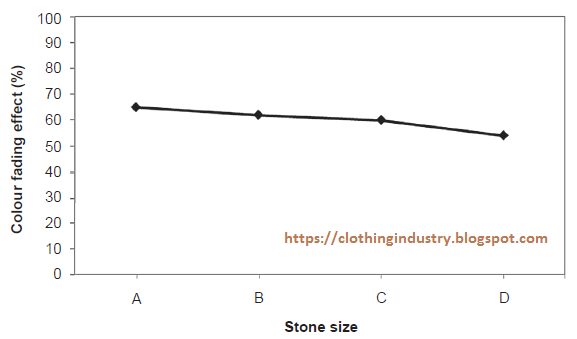

A: diameter = 2.0–3.5 cm; B: diameter = 3.6–5.0 cm; C: diameter = 5.1–6.5 cm; D: diameter = 5.5–7.0 cm.

EFFECT

OF STONE SIZE:

The above Figure shows the effect of stone size on the colour fading effect. It is

noted that the smaller the stone size, the better is the colour fading effect.

In addition, small stones can provide an even and uniform abrasion effect, but

the colour contrast produced is not good when compared with large stones.

A: diameter = 2.0–3.5 cm; B: diameter = 3.6–5.0 cm; C: diameter = 5.1–6.5 cm; D: diameter = 5.5–7.0 cm.

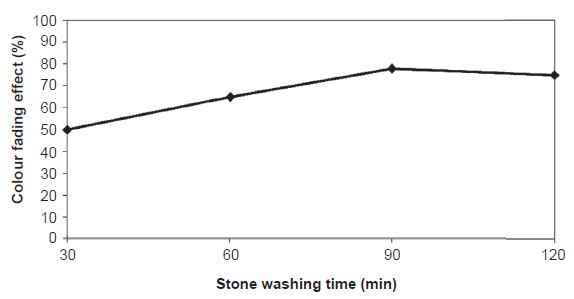

EFFECT

OF STONE WASHING TIME:

The above figure shows the colour fading effect under the influence of stone washing

time. It is shown that after 90 min, there is no further increase in the colour

fading in denim garments.