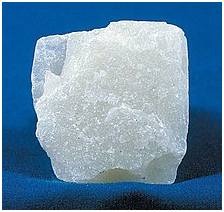

USES OF TALC (SOAP STONE) IN GENERAL

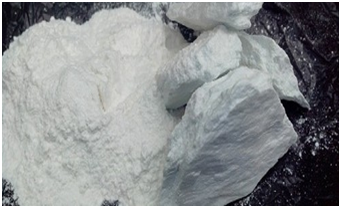

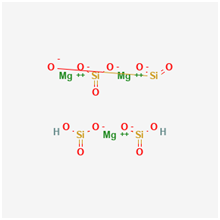

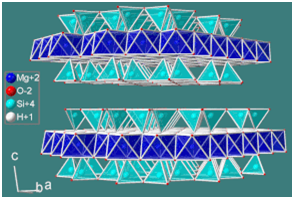

Talc basically

has five characteristics that make it a valuable mineral for industrial and

domestic applications.

i. Softness

ii. Chemical inertness

iii. Lamellarity

iv. Whiteness

v. Affinity for Organic Chemicals

In fact, Talc is found in everything from animal feed to tires and has been for millennia. As long as 15,000 years ago, cave dwellers used Talc in their paints. For at least 5,000 years, it has been used in cosmetics, especially as a skin lightener, and 1,000 years ago, the Chinese began using it in their glazed pottery. Listed below are several of Talc’s uses for the industries of the world:

Talc's number one consumer is the Paper Industry. It is used as filler and coating for paper products. Furthermore, Talc helps control the paper's pitch while the paper is being processed. It improves paper smoothness, water retention in certain papers, and printability and runnability for coated papers.

The Ceramics Industry is another Talc consumer. The glazing and bodies of the ceramics rely on Talc to give ceramics their gloss, whiteness and shape. Dinnerware, Sanitary ware, tiles, porcelain, and electrical insulation are all part of ceramics made with Talc. It is also used as a flux and to control thermal expansion - particularly in catalysts and particulate filters.

Talc is a major ingredient in Paint & Coatings. It helps control glosses, improves durability, fights rust (anti-corrosive), prevents cracking, and enhances smoothness. Pigment control and stability are also applications that Talc adds to paint and coatings.

Food Industry:

- Additives in Foods : Talc coats some foods such as Chewing Gum, Candy and Cured Meat as an anti-sticking agent

- Olive Oil Processing: To improve oil extraction & clarity.

Due to Inert, soft and fragrance-retentive nature of Talc; it is used in the manufacturing of Cosmetic Products.

- The softness and oil absorption it offers make it a primary ingredient in blushes, eyeshadows and powder compacts.

-The oleophilic nature of Talc makes it popular for dusting on the body in both baby powder and body cream. It helps absorb wetness and odour produced by the human body.

- The powder can be applied to help in chaffing and rubbing of the body extremities.

- Foot powder is usually made from Talc, to help stop odour and wetness.

Talc used in cosmetics is required to be of high purity and is reduced to fine particles for preparation.

Soap Industry:

Since pre-historic age Talc is being used as soap that is why Talc is also named as Soap Stone. Reducing the cost of detergents, Talc acts as a carrier for many soaps. Talc is harmless to our skin and is inert making it the ideal mineral to put in detergents as a filler. Body soap is sometimes made of Talc. It acts as a filler and does not hurt the skin.

Plastics are involved with Talc as well. Talc adds the following properties to plastic:

- It improves impact-absorbing strength, gives stability, and helps in the electrical insulation of plastics.

- Talc helps to improve plastic's ability to resist chemical and heat forces, as well as improves plastic's hardness, tensile strength and stiffness.

- Talc has a huge demand as the filler mineral in plastics because it is platy, inert, and an electrical resistor.

RubberHoses, Membranes, Sealing, Stoppers & Tires:

Talc's many uses can also be found in Rubber Companies. It helps give rubber its bounce. Rubber hoses made with Talc are used in just about every automobile on the market. With its high heat resistance and bonding power Talc helps make the hoses less permeable.

Pharmaceutical Industry:

Many antifungal powders include Talc to help kill bacteria off and improve the odour of the body.

-Talc is used in many commercial antacids for stomach and indigestion problems. The high resistance of acids and chemicals in the stomach make Talc a good filler for the tablets.

-Many ointments include Talc because of its ability to not react with chemicals. These ointments are used to treat things like scabies and insect bites.

-Pills are often coated in Talc to help keep moisture out of them. This is why Talc is a vital pharmaceutical mineral.

In Dentrifices Industry:

Dentrifices are prepared by mixing suitable proportions of polishing agents like Talc, precipitated limestone, kaolin, calcium sulphate, calcium phosphate with gum, glycerin, soap and other chemical ingredients. In the manufacture of dentrifices, some quantity of Talc is used as a polishing agent. For use in dentrifices, high whiteness is critical. Talc is thus, a well-suited option as an ingredient for dentrifices. In addition to high whiteness Talc also imparts smoothness to the final product.

In Electrical Ceramic Product Industry:

Talc is a poor

conductor of electricity and is thus used in the manufacture of ceramic goods

required for the electrical industry. For this purpose, Talc must be high in purity. Iron oxide should not be more than 1%

which would otherwise increase the dielectric constant of the product as well

as impart an unattractive colour to it.

The CaO should not be more than 1.5% as it would increase the abrasiveness,

shorten the vitrification range and sometimes cause shrinkage during high

firing.

Talc in Agriculture Industry:

Talc powder prevents infestation of food grains from insects and pests and hence, it is sprinkled over food grains which is kept in big godowns. For use in agriculture, the right pH of the Talc powder is an absolute necessity.