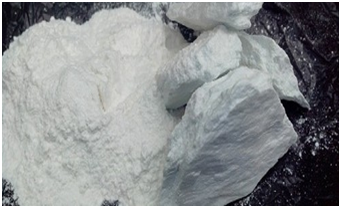

TALC IN PLASTIC INDUSTRY

1.Improved performance of plastic

products:

· Talc of extremely fine size and high aspect ratio can integrate within the polymer without increasing the distance between them. Therefore, it acts as a shock absorber and increases the impact resistance of the product.

· Talc particles can make weak molecular interactions with the polymer chains thereby improving mechanical properties like stiffness, resilience etc.

· Characterized by low coefficient of thermal expansion, Talc offers tremendous dimension stability to the plastic product.

· Talc’s flexible structure greatly increases the creep strength of the plastic product due to which even under chronic strain, it undergoes minimum deformation. This is critical for products that need to perform in high pressure conditions.

· Talc is lubricating in nature and thus reduces visibility of scratches on the product.

2.Improved

processing:

· Talc is lubricating in nature and thus reduces visibility of scratches on the product.

· Talc is a smooth and slippery substance. Thus, it acts as a good anti-blocking agent, preventing the plastic from unwanted adherence to different surfaces.

· Talc has low specific heat capacity due to which it decreases the duration of the heating and cooling cycle thereby increasing production speed.

· Being soft and non-abrasive, Talc minimizes abrasion of tools during production.